Piece Rate Payment System-Differential Method: Definition; Applicability; Example; Advantages And Disadvantages

1.1 General Definition

Piece Rate Payment system is a method of computing the labor cost for the employees which is pegged on the pieces an individual employee produces within a given period. This formula is categorized in to two broad types, namely:

Straight piece rate system

and

Differential piece rate system

2.1 Specific Definition

Differential Method is a Piece Rate Payment System which discriminatively rewards highly those employees who are hard working and contrary pays low rates to the less productive employees.

Definition-Two

Differential Piece Rate System is a Piece Rate Payment System affiliated approach is a method of computing labor cost where by an employee is paid at a higher wage rate for completing the job within a shorter time set or expected time. To the contrary, an employee is paid less if he or she takes more time than the set or expected time to complete the same job. The method was developed by F.W. Taylor.

2.2 Applicability of Piece Rate Differential Method

Differential Piece rate method or scheme is most appropriate in certain circumstances. Some of those circumstances where this scheme is applicable are;

1.Differential Piece Rate Method applies where work done is repetitive in nature.

That is, the Differential Piece Rate Method is more suitable where the workers keep on doing the same task or similar task every now and then.

2.Output quantity is measurable.

The differential Rate Method fits well where it is possible to count the total number of units produced by an individual employee within a specific timeline.

3.Differential Rate Method is appropriate where product quality of the product is controllable.

The Differential Piece Rate Method advocates that the quality of the product should be of a nature that can be gauged using universally accepted indicator.

4.Differential Rate Method allows the process of setting an equitable and acceptable piece rate for the units being produced.

The Differential Piece Rate Method is well fitting where it is possible to set piece rate for the laborer without much complexity or confusion.

5.Differential Piece Rate Method is suitable where there is intent to motivate employees if they work extra hard.

The Differential Piece Rate Method gives an allowance to the workers to exploit their potential by being paid extra if they deliver over and above the set expectations of the firm.

6.Differential Piece Rate Method works well where tools of production are always available.

The Differential Piece Rate System is well suiting when the production tools such as processing, designing or packaging equipment are always available to cater for any extra production when the employee feels like working more than usual.

2.3 Formula for Differential Piece Rate System

So, how is the total wage income computed under Differential Piece Rate System?

The progressive method uses a structure as follows;

Up to 1,000 units per day $0.25/unit

1001 units up to 1500 units per day $.40/unit

1501 units up to 2000 units per day $1.05/unit

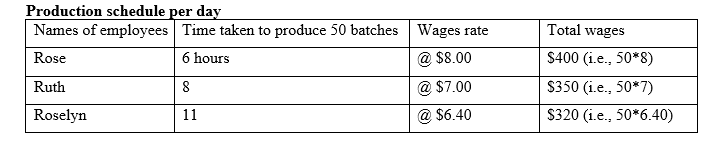

EXAMPLE ONE

Rose, Ruth and Roselyn work with a horticulture firm that deals with exportation of flowers. The terms of reference are that the employees are supposed to prepare batches of flowers ready for export such that each batch of flowers should have 10 sticks;

The management expects 50 batches per employee per day.

Wage payment terms and conditions.

Wage rate is $8 per piece (one batch) if production is done for less than a day.

Wage rate is $7 per piece (one batch) if production of a day’s output takes exactly a day.

Wage rate is $6.40 per piece (one batch) if production of a day’s output takes more than the pre-determined timeframe.

NB: A Day is 8 working hours

The following is a summary of production schedule for the three employees

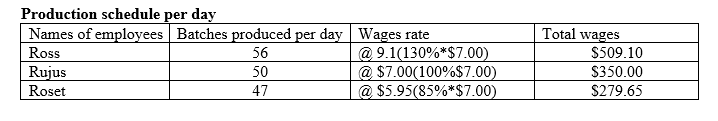

EXAMPLE TWO (ALTERNATIVE APPROACH)

Ross, Rujus and Roset work with a horticulture firm that deals with exportation of flowers. The terms of reference are that the employees are supposed to prepare batches of flowers ready for export such that each batch of flowers should have 10 sticks;

The management expects 50 batches per employee per day.

Wage payment terms and conditions.

Wage rate is 85% of the standard pay (i.e., $7 per piece) if production is done for less than 50 pieces per day.

Wage rate is $7 per piece (one batch) if an employee produces only 50 units which is a day’s output.

Wage rate is 130 % of the standard pay (i.e., $7 per piece) if production is done for more than 50 pieces per day.

NB: A Day is 8 working hours

The following is a summary of production schedule for the three employees

2.3.1 Advantages of using Differential Piece Rate System to Compute Labor Cost

1.Differential Piece Rate System helps the individual employees to be compensated as he or she expects. Such that efficient workers receive good reward.

2.Differential Piece Rate System is a method which is simplified as per employee’s output.

3.Differential Piece Rate System helps in regulating the overhead expense per unit. Such that the average cost per unit is lower than when this approach is absent.

4.Differential Piece Rate System promotes production efficient

The Differential Piece Rate System method ensures that efficiency in production is given preeminence so as to benefit the business.

5.. Differential Piece Rate System has the characteristic of simplicity in computation which makes it possible to determine the cost per unit of a product.

Since it’s easy to work with Differential Piece Rate System/method, computation of cost per unit of a product is possible.

6.. Differential Piece Rate System is Time saving

Differential Piece Rate System or method promotes time optimization such that more output is gotten at the end of the day. This is advantageous to the firm.

7.. Differential Piece Rate System aids in promotion of employee self-evaluation

When using the Differential Piece Rate System or method, the workers often set their own targets and therefore work towards achieving them.

8.. Differential Piece Rate System supports cost control function

Remember that control function is one of the management functions and therefore, the Differential Piece Rate System aids in assessing the deviations on costs and providing correction measures thereof.

9.. Differential Piece Rate System or method enables easier planning and control of production activities

With Differential Piece Rate System, the employer can smoothly plan for the production by setting targets which is a plus to the organization.

10.. Differential Piece Rate System is a source of innovations by the employees

Differential Piece Rate System prompts the individual employees to develop new methods of production or doing the same task and this helps in increased quality and quantity of output at the same time.

2.3.2 Disadvantages of using Differential Piece Rate System to Compute Labor Cost

- Differential Piece Rate System or method punishes both inefficient and innocent employees. For example, if one is sick or crippled, then this method has no mercy, you are paid as per your output.

- Causes adverse effect on the employee’s health status

An organization sticking to Differential Piece Rate System or method is a way of pushing the employees to much physical body exposure to straining which may result to physical sickness.

- Differential Piece Rate System leads to product quality deterioration

The terms and conditions of Differential Piece Rate System that it extends to employees try to complete many units within a short time, hence compromising the quality of output.

-

Differential Piece Rate System pushes the organization to more strict supervision.

Differential Piece Rate System calls for more costs to be incurred or paid to ensure that efficient supervision is carried out.